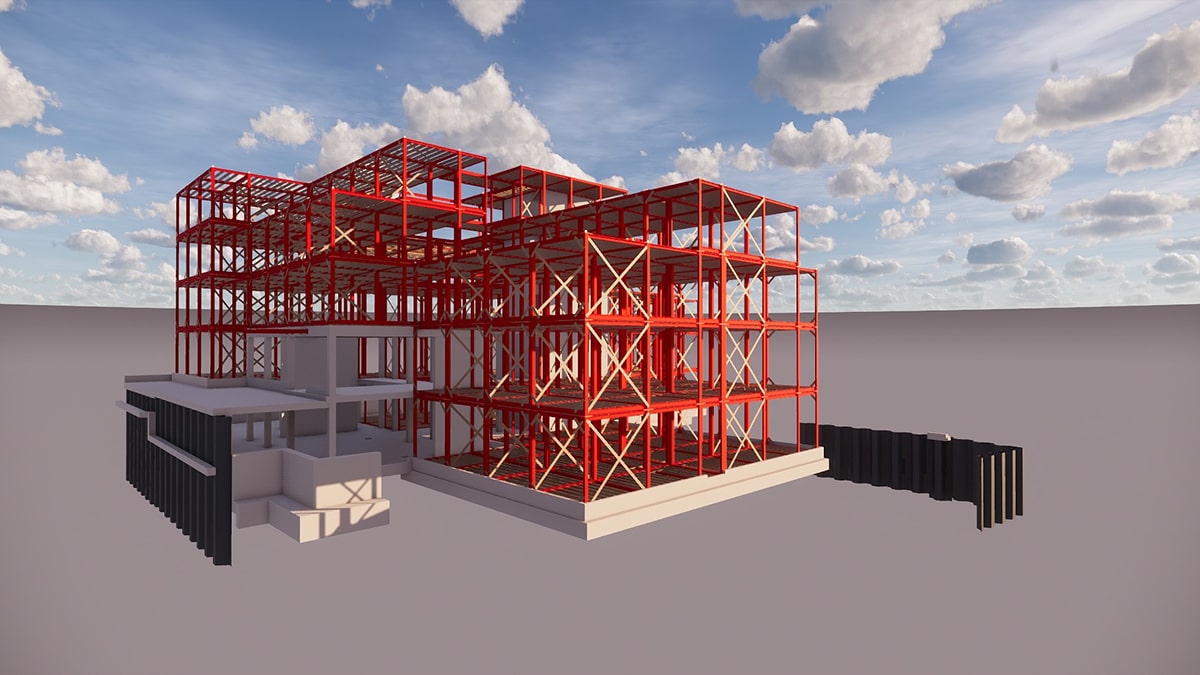

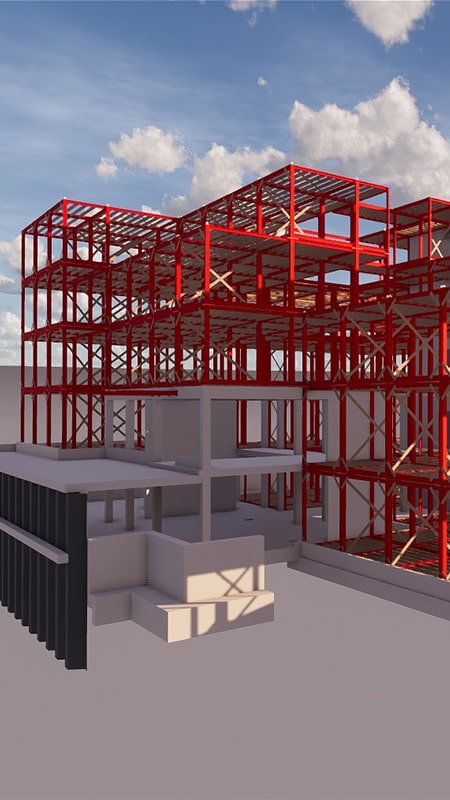

The Sparkford Road Project is a student accommodation building located in Winchester, UK. The structure is a hybrid of in-situ concrete frame and hot rolled steel modular units. The building is arranged over 5 floors including a single-storey basement. The building consists of 96 student rooms made of volumetric steel frames that come fully fitted on site and are joined via bolted connections. Due to the complex geometry of the building, a precast concrete core provides stability together with vertical cross bracing within the modules. RBG has developed the full modular system to suit the client’s requirements.

RBG Value Add

- Structural involvement during the early project stages is essential to simplify the building layout in terms of minimizing setbacks and transfers, but also in terms of rationalizing the structural section types. These items will help reduce the modular complexity/types.

- Extent of access for module-to-module connections is an essential item impacting all aspects of modular design and needs to be agreed in advance of detailed structural design stage.

- Fabrication tolerance is critical, modules need to be fabricated using a template and using strict QA checks.

- Modular connections to foundations to be post-drilled on site. More expensive than industry preferred holding-down bolts solution, but reduces risk significantly.

- Module-to-concrete locations to use steel embedded plates and connect the modules using typical steelwork connections.

- Modular installation contractor needs to be competent and experienced with this type of construction.

- Carry-out test installation that follows all the steps required.

- Either make module-to-module connection plates identical or make them so different that they cannot be confused on site.

- Plan for installation tolerance. For example, provide potential site weld locations if bolted connections cannot be achieved.

Key Technical Challenges

A congested site required early input from RBG construction engineering team into logistics and crane analysis. The definition of an efficient construction sequence was key to ensure buildability. Key challenges of modular construction such as tolerance and accessibility have pushed RBG’s capabilities to find innovative connection solutions. The risk associated with the supply chain of modular manufacturers was minimized by designing modular frames that can be procured from different steel fabricators.

Key Technical Innovation

The modular system developed has been optimized to reduce the number of module types by creating layouts that avoid transfers in setback locations. The system allows for early procurement and fabrication of the modules and can be adopted to suit different manufacturer’s capabilities and procurement strategies. It has the potential to be used for high rise buildings due to the innovative module to module connection design which can avoid cumulative out of tolerance, site welding or requirement for internal access.

Sustainability

Modular construction has multiple sustainability benefits:

- During modular production: use of local suppliers/local production, minimisation of waste due to factory-controlled environment.

- During site installation: reduction of temporary works, faster construction programme, use of local suppliers » minimize transport to site

- During end of life stage: potential re-use of steel members or module as a whole for temp accommodation, steel recycling.

Project Metrics

Building Metrics:

5 Storeys, 5120m2, 96 student rooms

Sectors:

Residential

Student Accommodation

Client:

Stelling Properties

Primary Contractor:

Stelling Properties

Project Metrics

Architect:

ACG (Previously Flanagan Lawrence and Studio Anyo)

Robert Bird Group Services:

Civil Engineering

Construction Engineering

Structural Engineering – including full development and design of modular system