- August 6, 2025

- 5:48 am

The Role of Structural Barrettes in High-Rise Construction

Introduction

Structural barrettes are deep rectangular foundation elements similar to piles, sometimes used in modern high-rise construction.

Barrettes can offer significant advantages over traditional bored piles, particularly in terms of load-bearing capacity, lateral resistance, and compatibility with top-up/top-down construction methods.

This article explores the fundamentals of barrettes, their installation process, and the benefits they bring to high-rise developments.

Understanding Barrettes

Barrettes are large rectangular foundation elements that function similarly to piles and can provide superior structural capacity. Unlike conventional piles, which have circular cross-sections, barrettes have a large rectangular cross section. This shape allows them to carry greater vertical and lateral or shear loads, making them ideal for supporting high-rise structures and contributing to the lateral stability of the foundation system.

A key advantage of barrettes is their ability to eliminate the need for a large pile cap at the base of a building’s core. In traditional pile foundations to support a building’s core, a large reinforced concrete cap is required to distribute loads across multiple piles. By contrast, the more desirable geometry of barrettes can allow a narrower and more impactful capping beam to transfer the loads into these elements. This can generate architectural benefits and a more spatially efficient foundation system capable of carrying the high axial and shear loads under a buildings core, particularly in soft soils.

Advantages of Barrette Walls in High-Rise Construction

- Enhanced Load-Bearing Capacity

Barrettes are rectangular in cross section, which gives them a significant advantage over conventional circular piles. This shape allows them to resist not just vertical loads but also shear (horizontal forces) and overturning forces (rotational effects caused by wind or seismic activity). These capabilities mean barrettes can act as part of the building’s stability system, making them ideal for supporting tall structures, especially those subject to large lateral loads. This is particularly valuable in sites with soft or weak soil, where barrettes can continue the buildings lateral stiffness to adequate material.

- Compatibility with Top-Up/Top-Down Construction

Barrettes are fundamental to enabling top-up/top-down construction. Once installed, they can provide full structural capacity – vertical, shear, and overturning – allowing above-ground construction to begin while excavation continues below. This dual-direction approach means teams can build up and dig down at the same time.

- Improved Construction Efficiency

The ability to use top-up/top-down construction directly contributes to faster project delivery by reducing the overall construction timeline. Additionally, barrette systems reduce sensitivity around construction sequencing – once in place, they give teams more flexibility in when and how excavation or other works proceed. They can also assist with reducing temporary basement propping, simplifying the build process.

Benefits for Clients

For our clients, the use of barrettes translates into several tangible benefits:

- Faster project delivery

Barrettes enable top-up/top-down construction, allowing above-ground and below-ground works to progress in parallel – significantly reducing overall construction time.

- Increased design flexibility

Their enhanced strength provides more freedom in construction sequencing and basement excavation methods, helping reduce delays or staging constraints.

- Optimised usable space

When used beneath core areas, the spacing between barrettes can often be utilised in architectural layouts – creating potential for more lettable or saleable areas.

- Improved performance on challenging ground conditions

Barrettes perform exceptionally well in soft or low-strength soils, making them ideal for projects near rivers or areas with deep alluvial deposits.

- Higher structural capacity

Unlike traditional piles, barrettes can resist vertical, shear, and overturning forces – making them ideal for supporting taller and heavier buildings.

- Reduced need for temporary works

Their stiffness and stability can lower or remove the need for basement propping, simplifying site logistics and reducing temporary construction costs.

Installation Process of Barrette Walls

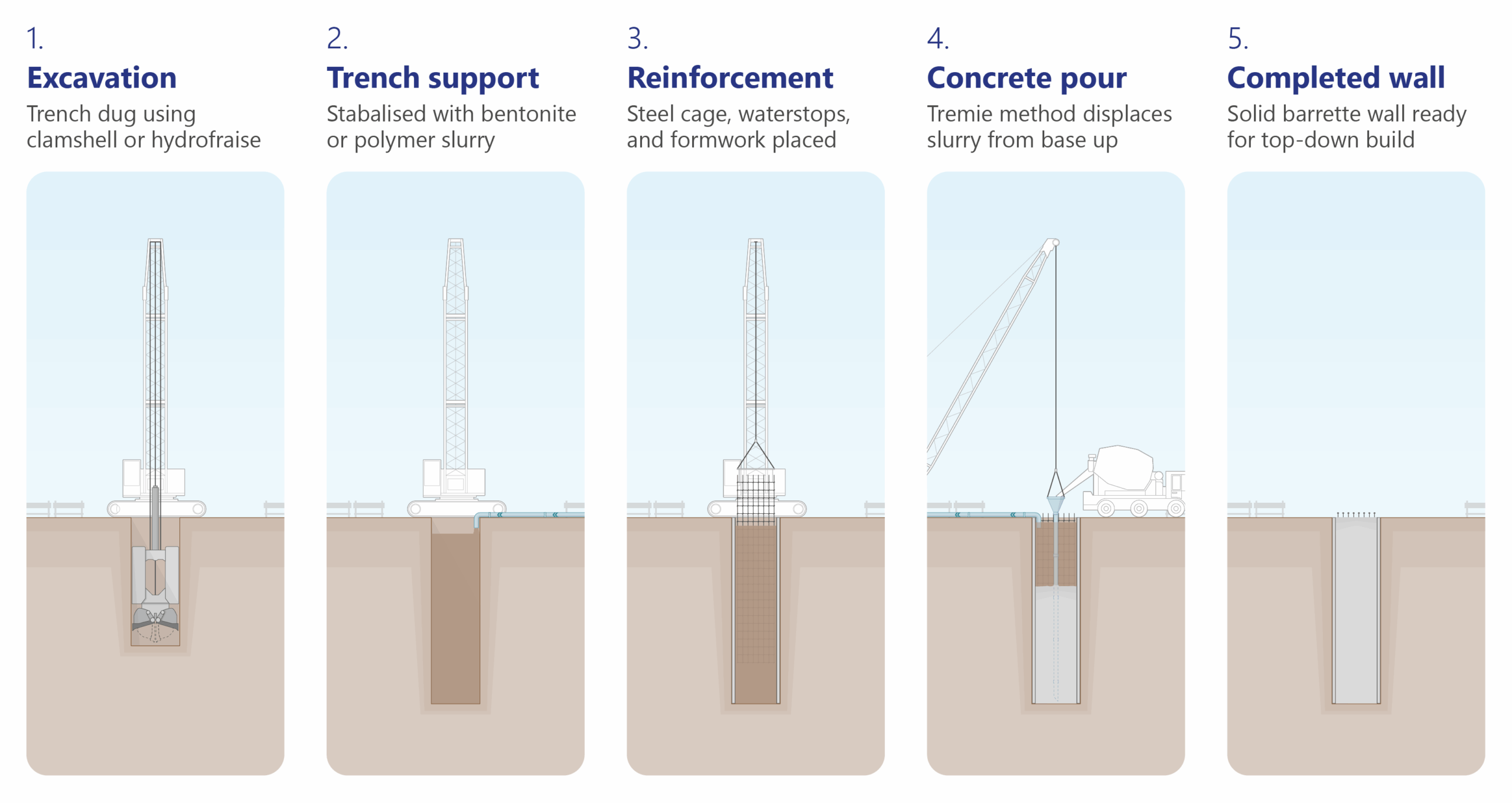

The construction of barrettes involves a series of precise steps to ensure structural integrity and stability:

- Guide walls

Barrettes are installed by first constructing guide walls at the piling platform level to define their shape and location.

- Excavation

Excavation is then carried out using a clamshell grab or a hydrofraise cutter, depending on the soil and rock conditions.

- Stabilisation with drilling fluid

During excavation, a drilling fluid – typically bentonite or a similar polymer stabilising agent – is introduced to support the trench walls and prevent collapse.

- Reinforcement cages, waterstops and stop-end formwork

Once the trench reaches the required depth, the drilling fluid is first cycled with fresh fluid to remove disturbed sediments and then reinforcement cages, waterstops, and stop-end formwork are positioned at the correct heights.

- Concrete is poured

Concrete is then pumped from the base using the tremie method, displacing the drilling fluid, which can be recovered and processed for reuse.

This graphic outlines the process of installing a Barrette:

Case Studies and Real-World Applications

Barrettes have been successfully implemented in numerous high-rise projects worldwide. In dense urban environments where deep excavations pose challenges, barrettes provide a practical solution.

One Barangaroo (Crown Sydney)

One Barangaroo (Crown Sydney), located in Barangaroo on the foreshore of Darling Harbour, is a landmark development featuring a six-star hotel, a members-only casino, private residences, and basement car parking. RBG was involved from the project’s inception in 2013, bringing global tall-building expertise to deliver innovative design and construction solutions. Notably, the team implemented a unique top-down jump-start construction method that accelerated the program, and barrettes were instrumental to this design.

Waterfront Brisbane

The collective transformation of Brisbane’s Eagle Street Pier, One Eagle and Naldham House will deliver a global-standard business and tourist destination with enhanced open spaces and amenity and a revitalised premier waterfront dining hub.

The Waterfront Brisbane development comprises two premium-grade commercial towers over a substantial retail podium adjoining the existing One Eagle commercial tower in Brisbane. The development includes four basements hard against the Brisbane River and the construction of a new Riverwalk connection from Riparian Plaza to Stamford Plaza.

The challenging site required an innovative foundation solution and barrettes were chosen due to their high shear and axial capacity to support the buildings’ core also allowing a top-up/top-down construction methodology. Utilising the high-capacity barrettes allowed the core to be constructed ahead of the basement construction and allowed a significant program saving over a typical open excavation that was also problematic given the four-level basement abutted the river. Barrettes were socketed into strong bedrock utilising a hydrofraise cutter rig to provide the substantial lateral and vertical load capacities.

Concept image, complements of Dexus and subject to change.

Conclusion

Structural barrettes play a vital role in modern high-rise construction by enhancing load-bearing capacity, simplifying foundation design, and enabling top-up/top-down construction. Their ability to support complex superstructures while improving construction efficiency makes them an attractive option for developers, contractors and engineers alike. As urban development continues to push the boundaries of height and design, the use of innovative foundation systems like barrettes will remain essential in shaping the skylines of the future.

| Authored by:

Dominic Howe, Senior Associate

|

Reviewed by:

|