Robert Bird Group partner with Limak Insaat to deliver the renowned Spotify Camp Nou Stadium project

Robert Bird Group Celebrates Five Project Wins at the CTBUH 2023 Regional Awards for Excellence

ICD Brookfield Place picks up a significant award at MEED Projects Awards 2022

ICD-Brookfield Place has won the most significant award at this year’s MEED Project Awards -Project of the Year 2022 across all sectors and regions within MENA – as well as picking up the win for Building Project of the Year in MENA. An amazing result for this landmark project in Dubai.

Continue readingNZ National Seismic Hazard Model Update

RBG has been operating in New Zealand for over 6 years. Our leadership team is made up primarily of NZ-trained engineers who have returned to NZ after working abroad in one of our many RBG offices across the globe. We are engineers who ‘grew up’ on seismic engineering, refining and expanding our technical skills while working on some of the world’s most complex engineering projects.

Continue readingThe Oxlade – Project Milestone

December saw the final pour of the Hydrostatic Basement floor at The Oxlade (80 Oxlade Drive, New Farm). This is a significant milestone for the team on-site and marks the end of a challenging excavation process through very difficult soil conditions. The Basement 3 Hydrostatic slab is typically 800mm thick with 1200mm thickenings and a section of a 2000 deep raft which enables the structures to span over a heritage sewer.

The Oxlade is a high-end luxury apartment building, architecturally designed by Bureau Proberts for developer Seymour Group. The site sits on top of a heritage sewer that can’t be disturbed or surcharged, so as a result the hydrostatic slab not only retains the hydrostatic pressure but transfers two cores, a shear wall, and 8 columns across a two-meter deep raft. The deep raft spans to a series of sleeved piles which run to a depth of circa 30m below raft level to transfer the loads to the underside of the heritage sewer. Congratulations to the team on this milestone! It will be a great project to follow.

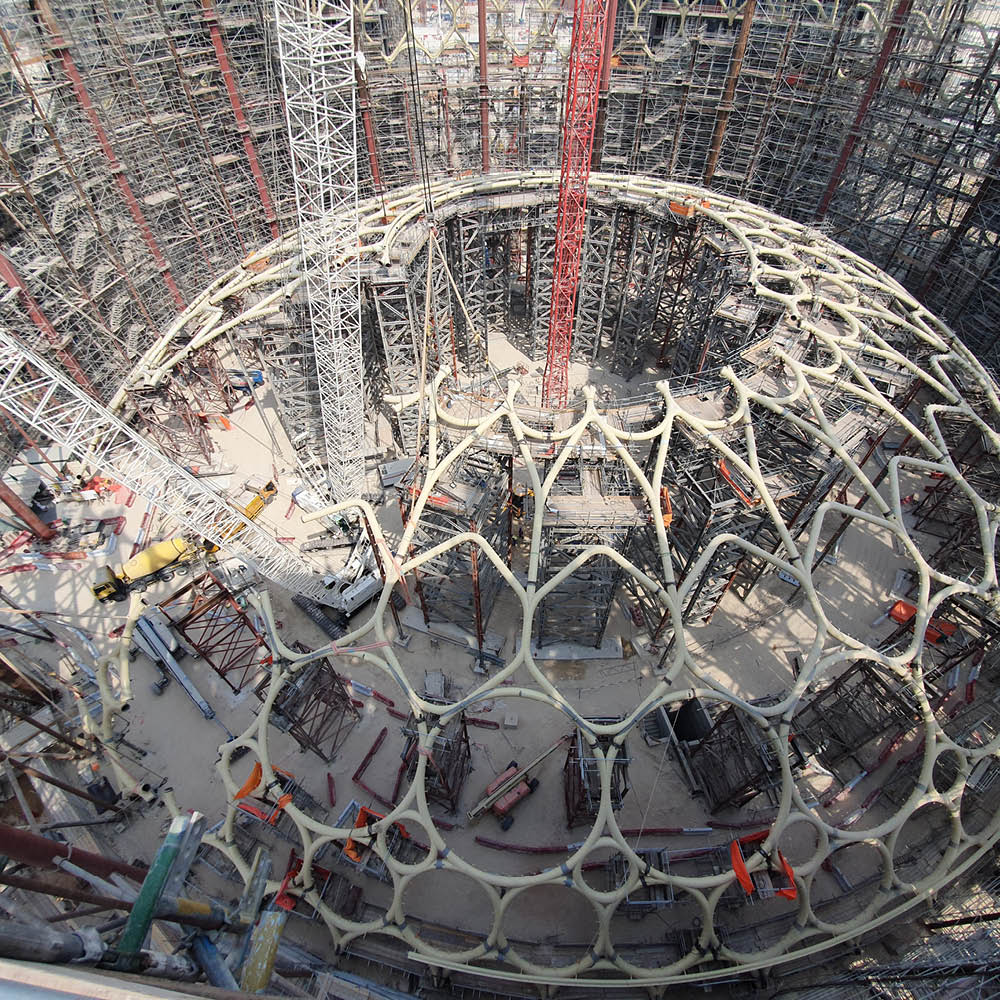

Continue readingEngineering the Heart of Expo2020

RBG, in collaboration with Cimolai Rimond Middle East, developed the Construction Methodology and Erection Sequence (CMES) for the Al Wasl Trellis, simulating the construction of the Trellis with a Digital Twin whilst also implementing predictive and live health monitoring of the strand jacking operation for the 900t ‘crown’ lifted in September 2019. RBG was awarded Consultant of the Year for its positive contribution to the centrepiece of Expo 2020.

Continue reading21 Moorfields (London)

Exciting times at 21 Moorfields as the final piece of lightweight concrete is cast onto the roof of the 17 storey 16,000T steel frame on 9th September 2021. Developed by Landsec with Structural, Civil, Geotechnical and Construction Engineering design by Robert Bird Group, the building will provide ~600,000sqft of premium office space, and is due for shell and core completion by Sir Robert McAlpine in 2022. The building is located directly over London Underground’s Moorgate Station platforms, Crossrail’s running lines, and the Moorgate Station Entrance to Crossrail’s Liverpool Street Station.

Maintaining station operations throughout construction was imperative, and the complex underground constraints left little space for foundations. Robert Bird’s solution for a 60m span ‘bridge’ building is founded on 70m long large diameter monopiles located within negotiated back of house station areas. Foundations were piled within steel sleeves through the station from a bespoke piling grillage sat on the station roof. This method enabled the station to remain fully operational with very little noise or disruption from the construction process.

Continue readingRobert Bird Group signs MOU to establish 3D Concrete Printing and Digital Construction Center

Robert Bird Group is proud to be an inaugural member of the American University of Dubai’s Centre for 3D Concrete Printing and Digital Construction. Working with fellow inaugural members Arabtec Construction and 3DVinci Creations, we look forward to driving the development of 3D Concrete Printing and Digital Construction in the UAE and wider GCC. We believe that 3D Printing presents a significant opportunity for the construction industry and we recognise that collaboration with 3D Printing specialists, contractors and academia is critical to realise the benefits of the technology for both the industry and society.

Continue readingSignificant milestone for the BSCU project

Robert Bird Group are pleased to see the successful installation of the temporary support truss which marks a significant milestone for the Bank Station Capacity Upgrade Project. The truss which supports 4 levels of basement slab within the 18.5m deep piled basement structure, enables construction of a new 8 level deep Bank Station entrance. This innovative approach eliminates the detrimental programme and H&S impacts of the plunge column alternative within the low level 20m deep SCL shaft. The shaft houses the lift and stairs, and is adjacent to an inclined escalator barrel, both of which are subsequently constructed from the base of the piled box.

Continue reading